Cable tension reduction device OMEGA series

Application:

For protection of overhead distribution lines against mechanical overloads.

Ice, frost and wet snow on distribution lines, as well as fallen trees, can significantly increase the stress on conductors, which in turn can lead to damage to poles and crossarms, resulting in long-term power outages, costly repairs and even the need for complete reconstruction of the line.

Conductor tension control devices (DACs) are used to protect posts and crossbeams. They are designed to provide additional sag in spans when conductor tension exceeds allowable values.

- A universal and reliable concept ensuring long line uptime

- Independent protection for each cable to prevent support failure due to twisting

- Easy installation and replacement

- Possibility of immediate, temporary increase in cable sag

- All parts of the OMEGA are hot-dip galvanized to provide effective protection against corrosion

- The OMEGA device is patent protected

The OMEGA device allows the line to withstand overloads caused by wet snow, ice or wind up to 30% higher than the maximum tension.

| Symbol | Length [mm] | Nominal force F [daN] | Relaxation length D [mm] | Number of pieces in the package |

|---|---|---|---|---|

| DAC2500A | 600 | 250 | 260 | 1 |

| DAC2500B | 600 | 250 | 390 | 1 |

| DAC3150A | 600 | 315 | 260 | 1 |

| DAC3150B | 600 | 315 | 390 | 1 |

| DAC4000A | 600 | 400 | 260 | 1 |

| DAC4000B | 600 | 400 | 390 | 1 |

| DAC5000A | 600 | 500 | 260 | 1 |

| DAC5000B | 600 | 500 | 390 | 1 |

| DAC6300A | 600 | 630 | 260 | 1 |

| DAC6300B | 600 | 630 | 390 | 1 |

| DAC8000B | 600 | 800 | 390 | 1 |

| DAC8000C | 600 | 800 | 520 | 1 |

| DAC10000B | 600 | 1000 | 390 | 1 |

| DAC10000C | 600 | 1000 | 520 | 1 |

| DAC12500B | 600 | 1250 | 390 | 1 |

| DAC12500C | 600 | 1250 | 520 | 1 |

| DAC16000B | 600 | 1600 | 390 | 1 |

| DAC16000C | 600 | 1600 | 520 | 1 |

| DAC20000B | 600 | 2000 | 390 | 1 |

| DAC20000C | 600 | 2000 | 520 | 1 |

| DAC25000B | 600 | 2500 | 390 | 1 |

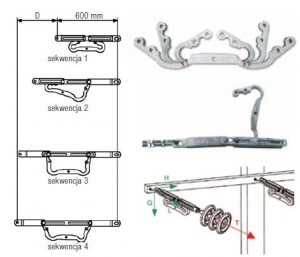

Each type of DAC OMEGA device has a specific elasticity expressed as “F”. When the tension in the wire exceeds its elastic strength, the OMEGA elastic element begins to gradually and smoothly open due to plastic deformation of the arms. As shown in the figures below, the operation of the DAC OMEGA device consists of 4 sequences.

Determining the nominal flexibility f of the DAC OMEGA is necessary to ensure proper operation; “F” is a function of the maximum allowable conductor tension (T), which in turn is a function of the end post setting as well as the vertical (Q), transverse (H) and longitudinal (L) loads.

Mechanical line protection

Contact us

Puławska 366

02-819 Warszawa

| Symbol | Length [mm] | Nominal force F [daN] | Relaxation length D [mm] | Number of pieces in the package |

|---|---|---|---|---|

| DAC2500A | 600 | 250 | 260 | 1 |

| DAC2500B | 600 | 250 | 390 | 1 |

| DAC3150A | 600 | 315 | 260 | 1 |

| DAC3150B | 600 | 315 | 390 | 1 |

| DAC4000A | 600 | 400 | 260 | 1 |

| DAC4000B | 600 | 400 | 390 | 1 |

| DAC5000A | 600 | 500 | 260 | 1 |

| DAC5000B | 600 | 500 | 390 | 1 |

| DAC6300A | 600 | 630 | 260 | 1 |

| DAC6300B | 600 | 630 | 390 | 1 |

| DAC8000B | 600 | 800 | 390 | 1 |

| DAC8000C | 600 | 800 | 520 | 1 |

| DAC10000B | 600 | 1000 | 390 | 1 |

| DAC10000C | 600 | 1000 | 520 | 1 |

| DAC12500B | 600 | 1250 | 390 | 1 |

| DAC12500C | 600 | 1250 | 520 | 1 |

| DAC16000B | 600 | 1600 | 390 | 1 |

| DAC16000C | 600 | 1600 | 520 | 1 |

| DAC20000B | 600 | 2000 | 390 | 1 |

| DAC20000C | 600 | 2000 | 520 | 1 |

| DAC25000B | 600 | 2500 | 390 | 1 |

Each type of DAC OMEGA device has a specific elasticity expressed as “F”. When the tension in the wire exceeds its elastic strength, the OMEGA elastic element begins to gradually and smoothly open due to plastic deformation of the arms. As shown in the figures below, the operation of the DAC OMEGA device consists of 4 sequences.

Determining the nominal flexibility f of the DAC OMEGA is necessary to ensure proper operation; “F” is a function of the maximum allowable conductor tension (T), which in turn is a function of the end post setting as well as the vertical (Q), transverse (H) and longitudinal (L) loads.