DBI technology

Environmental concerns have become one of the main drivers of change in the maritime industry. Increasing regulatory requirements, the pursuit of emission reductions, and the development of electric and hybrid propulsion systems mean that every kilogram of equipment now has real significance. In response to these challenges, DBI technology was developed – a solution that allows for the replacement of heavy copper cables with lighter aluminum wires.

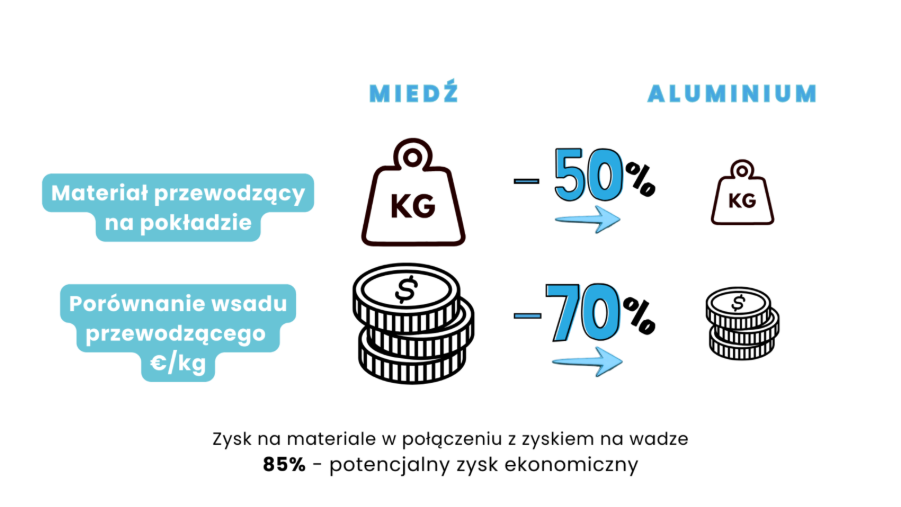

DBI technology is a solution that offers a range of benefits for manufacturers and owners of vessels – from cost optimization and increased fleet durability in operational conditions to increased cargo capacity. Instead of heavy copper cables that add weight to the fleet, lighter aluminum cables are used, offered as a set with specialized fittings and tools.

Advantages of DBI Technology:

– Weight reduction and optimization

– Optimizing costs, fuel consumption, and increasing payload capacity.

– Technology tested under conditions encountered during daily use:

- thermal shock,

- vibrations,

- tensile strength,

- heating cycles,

- short circuits,

- salt mist,

- waterproof,

- temperature and humidity

– System with DNV certification

What does the system include?

– flexible aluminum cable

– MTR copper terminal (cross-sections: DBI 95-12, DBI 120-12, DBI 150-12)

– SH450JCM crimping head (included with a storage case and space for dedicated dies)

– pompa SVEPT20-520JCM (pakowana w walizkę)

– Hydraulic hose for connecting the pump to the SF30J MTR head.

– Olympic Bibby

- The main reason for the test installation was to gain experience with cables and connections in harsh environments (North Sea), where the vessel had a contract for 3 years.

– Olympic Artemis

- On the Olympic Shipping ship, pływającym od 5 lat na morzu, w 2015 r. zainstalowano 3000m 3×150 EMC VFD.

– Electric Passenger Ferry Shipyard Bröderne AA

- W 2019 na aluminiowym Elektrycznym Promie Wycieczkowym Zainstalowano 1400m kabla.

– 5 car ferries from Shipyard Fjord 1

- The conversion of the ships to hybrid propulsion was made possible by installing 5000 meters of cable on each ferry.

Contact us

Puławska 366

02-819 Warszawa